+86 28 84400953

+86 28 84400954

Telegram: Whatsapp:+86 1390 8045 028 Wechat: t120363814

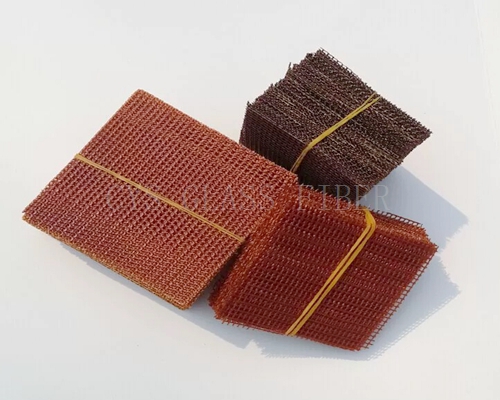

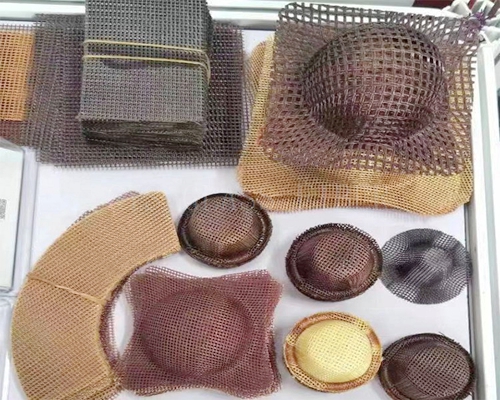

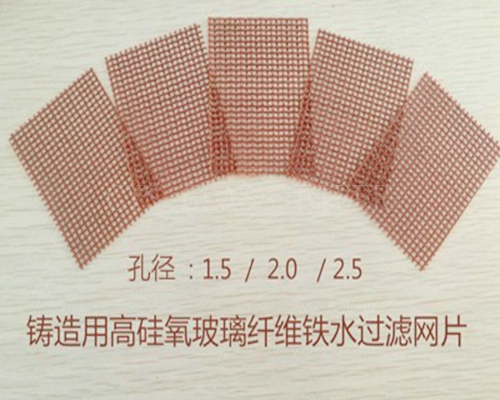

High Silica Fiberglass Filter Mesh for Molten Aluminum Steel Foundry Filtration

Product Features:

• Low cost and easy to use.

• Improves fluidity and metal distribution.

• Removes micron sized inclusions and impurities.

• Can be used with existing pattern equipment.

• Eliminates inclusions created by ceramic chips.

Product Parameters:

|

SiO2 content |

≥96% |

|

Softening Point |

1700℃ |

|

Working Temperature |

≤1620℃ |

|

Sustaining Working Time |

5 minutes |

|

Tensile Strength |

16kg/4 ends |

|

Color |

Dark brown, black |

|

Mesh Size |

0.8mm/1.0mm/1.5mm/2.0mm/2.5mm |

|

Density |

300-600 g/cm2 |

|

Thermal Shock Resistance |

≥2times/1100ºC‐Room temperature |

Specification:

|

Item |

Density |

Mesh size |

Porosity |

SiO2 |

Thickness |

|

HSWM-15 |

580g/m2 |

1.5x1.5mm |

0.19 |

≥96% |

0.98mm |

|

HSWM-20 |

460g/m2 |

2.0x2.0mm |

0.24 |

≥96% |

0.98mm |

|

HSWM-25 |

350g/m2 |

2.5x2.5mm |

0.33 |

≥96% |

0.98mm |

Note: other specifications made as requests.

Application:

- Cut pieces for in mold filtration like sand casting, gravity casting, etc.

- Cut pieces for riser sleeves, bottom or across ports in walls.

- Cut pieces to provide a weakened plane for riser knock-off.

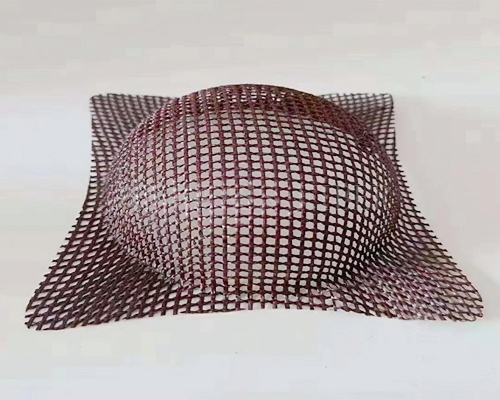

- Cup shapes for investment casting.

Packaging:

The product can be packed on paper tube.

|

Coil height (mm) |

245 |

|

Tube bottom diameter (mm) |

40 |

|

Tube top diameter (mm) |

27 |

|

Package weight (kg) |

0.5~1.0 |

|

Number of layers |

1 |

|

Number of coils per layer |

25,30 |

|

Net weight per carton (kg) |

15~25 |

Storage: