+86 28 84400953

+86 28 84400954

Telegram: Whatsapp:+86 1390 8045 028 Wechat: t120363814

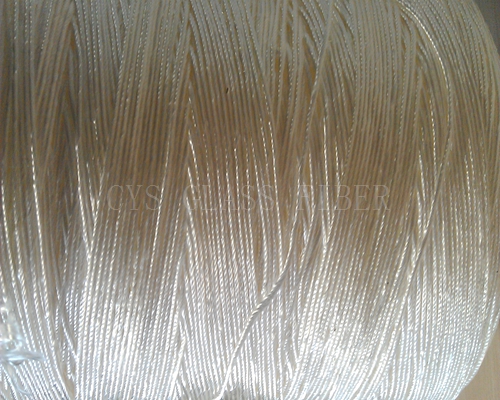

High Silica Twist Wick for E-cigs

High Silica Twist Wick for E-cigs is specially produced for E-cigarette atomizer. It is twisted of special glass fiber yarn into rope and sintered at high temperatures. It can be worked above 1000°C for long-term and melting point 1700 °C. It is characterizes good oil absorption, high temperature resistance, no toxic, no odor, long life working, etc.

|

Type of glass |

High silica |

|

Product code |

CYS-HS54R |

|

Diameter (mm) |

0.5~3.5 |

|

Linear Density (tex) |

350~4800 |

Product Features:

1) High oil absorption.

2) Quick oil guide.

3) No odor.

4) High temperature resistance.

5) Low fuzz.

6) Uniform thickness.

7) No harm to human body.

Meet the 6 test requirements in ROHS

Application:

Especially for E-cigarette atomizer. It can also be used in hair drier and electric oven, etc.

Technical Parameters:

|

Content of SiO2 |

Linear Density |

Diameter |

LOI |

Structure |

|

≥96% |

±5% |

±10% |

<4% |

Twist |

Packaging:

The product can be packed on paper tube.

|

Coil height (mm) |

245 |

|

Tube bottom diameter (mm) |

40 |

|

Tube top diameter (mm) |

27 |

|

Package weight (kg) |

0.5~1.0 |

|

Number of layers |

1 |

|

Number of coils per layer |

25,30 |

|

Net weight per carton (kg) |

15~25 |

Storage:

High Silica Fiberglass Rope/ wick should be stored in its original packaging in a dry and cool place. Best conditions are at temperatures from 15 to 35°C and humidity between 35 and 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layer, care should be taken to correctly and smoothly move the top pallet.